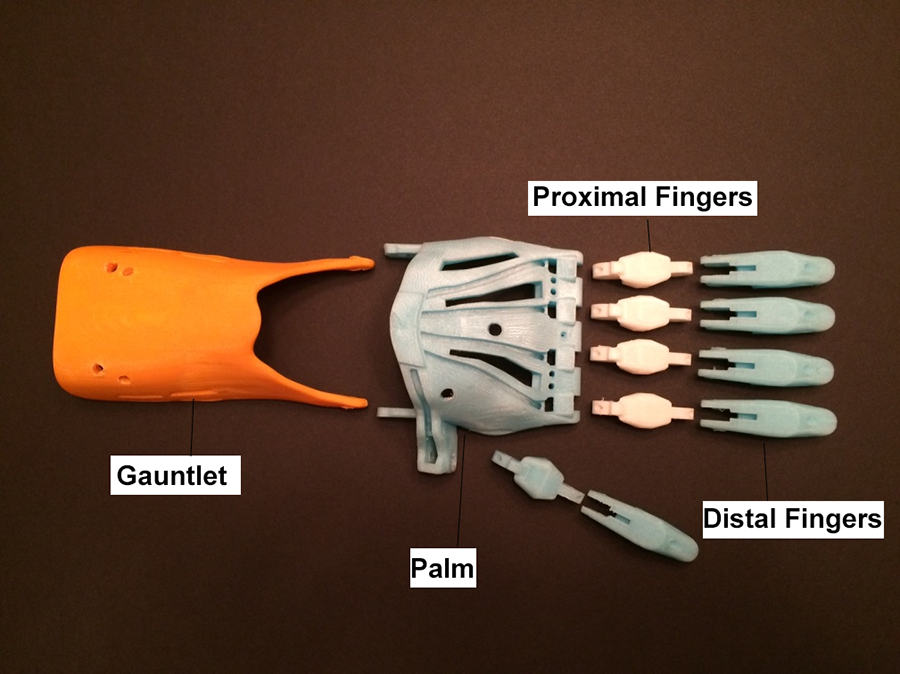

Before beginning assembly of the Cyborg Beast, first identify all the pieces from the 3D printing.

The proximal finger sections are closer to the palm with the distal section being the finger tips. Notice that the 2 pieces for the thumb are slightly different in that the distal finger is smaller than the rest and the proximal finger is wider.

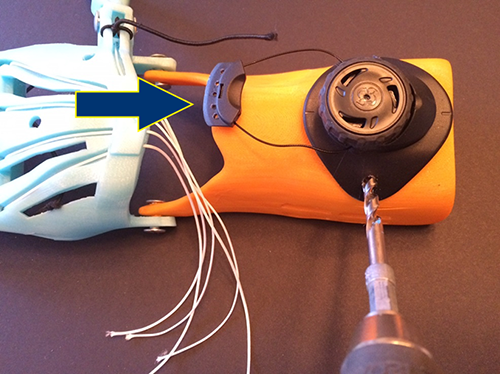

Drilling

All sections that are to be secured with a Chicago screw must be drilled with a 7/32” bit. If you are assembling a small hand, you may need to start with a smaller bit and work up to a 7/32” bit in order to avoid splintering the plastic.

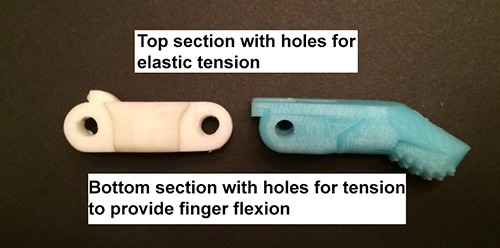

All smaller holes that support both the elastic cord and the tension cord must be drilled to clean out excess debris. The finger sections must be drilled on both the top (for the elastic cord) and the bottom (for the tension cord). A 1/16th drill bit is sufficient for the opening on the bottom section. However, depending on the size of the hand to be assembled, a slightly larger drill bit may be used for the top holes.

Remember to drill the holes on the palm section where the tension cord will be threaded to reach the gauntlet.

Filing

Using a small file, smooth all rough edges of the plastic pieces. A nail file or emery board may be used in place of a small file. Depending on the quality of the printing and the size of the hand, there may be minimal filing or more involved filing to be done.

Once all the rough edges are smooth, assemble the proximal and distal finger sections with a Chicago screw. The finger should move freely through the full range without limitations. If the range is limited or there is friction with movement, remove the screw and file the rounded end of the proximal finger piece until there is full and free movement at the joint. Additional filing of the sides may also be necessary.

Elastic Cords

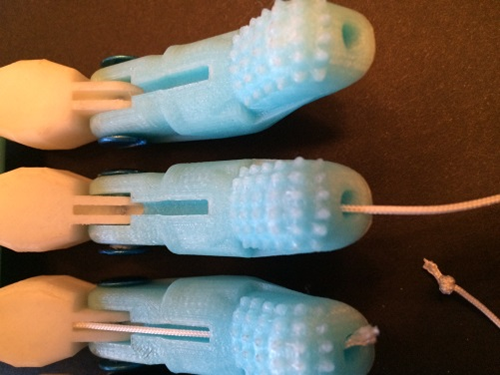

Choose elastic cord that is best suited for the size of the Cyborg Beast hand that is being assembled. For a larger hand, 2mm elastic cord is appropriate. For a smaller hand 1.5 mm elastic cord will be sufficient.

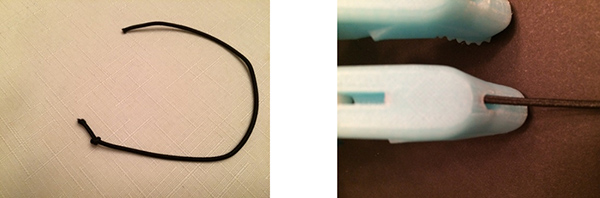

Cut 5 pieces of elastic cord approximately 7 inches long. At one end of the cord secure a knot. If using thinner cord, 2 knots may be required to keep the elastic from slipping back through the finger.

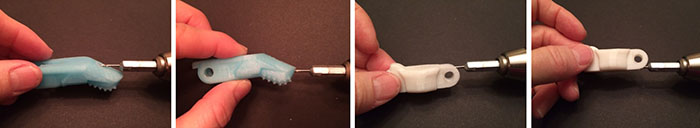

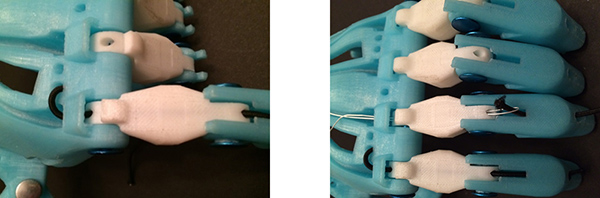

Begin by threading the cord through the top of the distal finger piece. Proceed to thread the elastic cord through the proximal finger piece as shown. The end of the cord is then threaded down through the palm section.

Tip: If it is difficult to push the cord through the holes, a thin piece of wire or nylon thread can be used to assist with pulling the cord through. Fold a thin wire or nylon thread in half and push it through the hole. Loop the wire around the cord end and pull back through the hole. A pair of tweezers or needle nose pliers can be helpful in manipulating the cords.

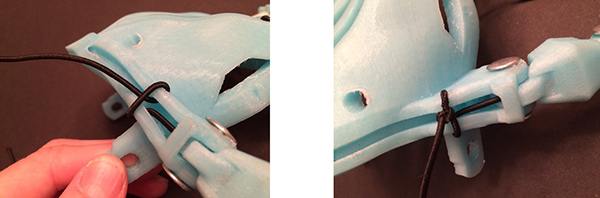

The thumb elastic cord is pulled through and secured as pictured below. Before tying the knot, pull on the cord to make sure the knot will is secure and will not pull through the end of the finger. Then adjust the tension in the cord so that it is adequate to just maintain the finger in the straightened position. Too much tension will require extra force by the prosthesis user to achieve finger flexion.

With the fingers, adjust the tension in much the same manner, assuring that tension is adequate but not too much. Secure the 2 cords on the palmer surface with a square knot. If tension adjustments are required later, the knots can be untied and adjusted as necessary.

Tension Cords

Using 1.5 mm nylon cord cut 5 sections that are 14 inches in length. Secure a double knot at one end of the cord. Beginning at the distal finger section on the bottom side, thread the cord from the distal to the proximal section.

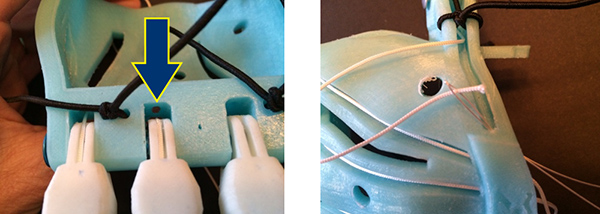

The cord must be fed through the small hole in the palm section (as pictured) to the top of the palm. To assist with threading the cord through the small hole, a thin wire can again be used to help pull the cord through.

Gauntlet

Secure the palm and gauntlet sections using 2 Chicago screws. If necessary, enlarge the holes by drilling with the appropriate bit. Again, if the holes are quite small, start with a smaller bit and incrementally enlarge the hole using larger bits. This will help to prevent cracking or slivering of the plastic.

Tensioner

For the BOA tension system, small holes need to be drilled in the plastic bar for the tension cords to be secured.

With the tensioner centered on the gauntlet and near the edge, drill holes on both sides through the tensioner and the gauntlet. Holes can be cut into the strapping material to correlate to the holes just drilled. With Chicago screws, secure the strap to the gauntlet on the bottom side, while securing the tensioner on the top.