The Machining and Prototyping Core Facility involves the use of three major facilities within the University of Nebraska at Omaha Biomechanics Research Building:

- Machine Shop

- Design Studio

- Additive Manufacturing Laboratory

The most basic function of the Core is to provide services that utilize these spaces and their personnel and equipment. These services are for professionals in the University of Nebraska system, the local area, but also for people outside our state to progress their research or other projects.

This core can design, prototype, manufacture and repair, maintain, or install a wide range of devices and instrumentation. Individuals interested in the use of the Machining and Prototyping Core Facility services can fill out a project initiation form.

Machine Shop

The 1223 square foot Machine Shop is equipped with both traditional and advanced machinery that allows for the construction and fabrication in woods, metals, plastics, and unique composite materials. Equipment in the space includes a wide assortment of hand tools, and traditional subtractive manufacturing equipment. In addition to the tooling, several design workstations running the Autodesk Suite, Adobe Creative Cloud, and Solidworks are used by staff and student engineering technicians. The machine shop was also designed for typical prosthetics casting with a plaster modification area with grated, recessed flooring, and oversized fume hood for carbon fiber lamination. The Research Development Engineers have their offices in the machine shop and are available for designing and manufacturing devices needed for research. Primary equipment in the Machine Shop includes:

- CAD Workstations

- Bridgeport Knee Mill

- HandyScan 700

- Metalworking Tools

- Metal/Wood/Plastic Working Tools

- Hurco TM6i Turning Center

- Emcomill E350 3-Axis Micomachining Center

- GlobalMAX 1509 Waterjet

- Fanuc C400iC Wire EDM

- Hurco VM10i 3-Axis Machining Center

Design Studio

The Design Studio is a 470 square foot space that is dedicated to supporting student researchers in planning, conceptualizing, design, and basic fabrication for research projects. The studio is equipped with workstations capable with of industry-grade CAD software, simulation, and analysis. Also available to studio users are basic hand tools, power tools, a laser cutter, 9 Prusa printers, collaborative creative spaces, and functional prototyping layouts.

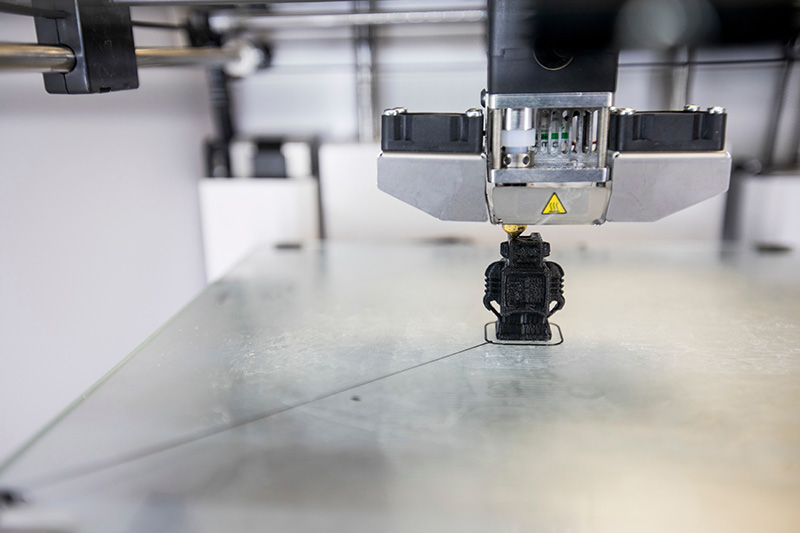

Additive Manufacturing Laboratory

The Additive Manufacturing Laboratory includes a primary 675 square foot space for general activities and a secondary 224 square foot space designed specifically for printing metal components. The laboratory is equipped with a wide range of 3D printers, ranging from industrial to commercial grade, and capable of printing many different polymers and metals. Primary equipment of the Additiive Manufacturing Laboratory includes:

- ProX DMP 320

- Connex3 Object 260

- Raise3D Pro 2 Plus

- uPrint SE Plus

- Fused Deposition Modeling (FDM)/Fused Filament Fabrication (FFF) 3D Printers

- Sintratec S3 Selective Laser Sintering 3D Printer

- BCN3D Epsilon W50

- 3DPlatform 300 Series Workbench Pro

- Bambu Lab X1 Carbon

- Form 3+

Rates

Internal: $75

External: $110

Current rates as of 7/1/2025

Forms

Personnel

Dr. Brian Knarr, Core Facility Director

Mr. Andrew Walski, Research Lab Engineer

Mr. Shubhankar Desai, Research Lab Engineer

MAPRO Primary Available Services

| Primary Available Services | Service Definitions |

|---|---|

|

Ideation/Conceptualization |

MAPRO offers consultation services with the Director, the Lead Machinist and Design Technician, and the Resource Mentor to help investigators understand new technologies and form new project ideas and concepts by leveraging engineering experience in related fields. |

|

Design |

MAPRO provides customized design solutions to deliver innovative support to researchers and businesses alike. These services engineering expertise to turn complex challenges into implemented opportunities. Design solutions are catered to the scope of user projects and range from engineering drawings, illustrated layouts, and three-dimensional modeling. |

|

Prototyping |

Using digital fabrication technologies including 3D printing, laser cutting, and computer numerically controlled (CNC) milling and turning machines, MAPRO provides rapid prototyping services that can transform concepts into usable prototypes within short timelines. |

|

Manufacture |

MAPRO can perform short-run manufacture of products in support of research and development that typically range from 10-100 individual units. Tools leveraged as part of this service include CNC mills, lathes, 3d printing, and fully equipped assembly stations. |

|

Installation/Utilization |

Installation services offered by MAPRO typically involve the fitting of sensors or instrumentation suites into custom settings including laboratories, vehicles, or wearables. |

|

Modification |

Modification of existing devices or instrumentation is also offered by MAPRO. This service allows the adjustment of tools, sensors, or major devices to better suit users’ needs, permitting the collection of unique data that requires physical, electrical, or software-based changes. |

|

Validation |

Using laboratory-grade instrumentation, MAPRO can perform analyses to validate the effectiveness of user-provided devices or prototypes. This service includes universal testing for compression, tension, and torsion, as well as handheld metrology. |

|

Measurement |

MAPRO provides dimensional coordinate measurement inspection services in addition to traditional quality and validation procedures completed with certified measuring equipment. |

|

Repair |

Repair and maintenance of commercial and custom MAPRO equipment. This service is ongoing in support of many projects and ensures that projects’ instrumentation is working properly to minimize downtime during data collection and analysis |